PRODUCTS

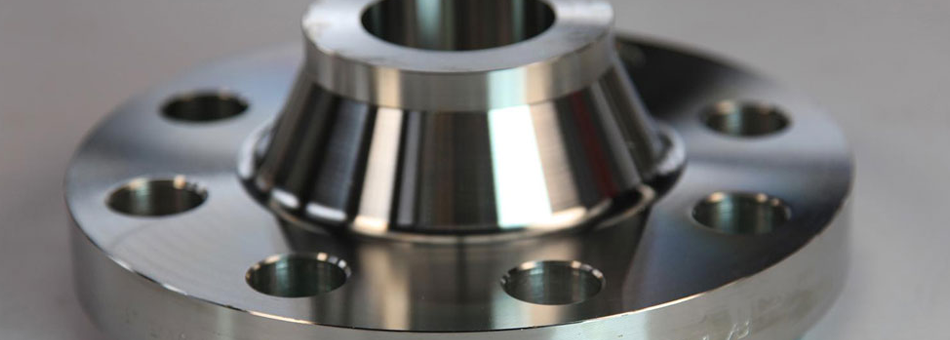

Pipes & Tubes

We are engaged in offering wide range of Pipes and Tubes in copper alloy pipes, nickel alloy pipes, stainless steel pipes, stainless steel duplex pipes, copper & alloy steel and nickel & copper alloy material. These are widely used in ship building, aircraft & aerospace, drilling & well building industries. Our range like copper alloy pipes, nickel alloy pipes, stainless steel pipes, stainless steel duplex pipes available in various grades and specifications to suit the requirements of clients.

| Stainless Steel & Duplex Pipes | |||||||||||||||||||||||||||

Stainless steel pipes and Stainless steel Duplex pipes feature excellent flow characteristic with higher strength and better stress corrosion cracking resistance. These Stainless steel pipes can be employed for high temperature and pressure applications. We can offer these pipes in different dimensional specifications based upon the requirements of the clients. Our stainless steel and duplex pipes can be easily welded to the system for a leak proof joint. Features :

Specifications of Duplex Steel :

|

|

| Carbon & Alloy Steel Pipes | |

Our Copper and Alloy Steel Pipes are widely used for in Air conditioning and refrigerating systems. These pipes provide easy workability and can be bent an appropriate bending machine. The light ability to withstand high internal pressure makes our pipes ideal for most hot and cold water, central heating and gas services installations. These pipes can also be used for variety of other industrial applications. Features :

Carbon Steel : ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B , API 5L X 42, ASTM A333 GR.6 Alloy Steel : ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 |

|

| Carbon & Alloy Steel Tubes | |

We offer a wide range of Carbon and Alloy Steel Tubes for application in marine, shipbuilding, pharmaceuticals, paper, textile, sugar, dairy and other industries. These tubes are widely acknowledged for optimum tensile strength, corrosion resistance and durability. Designed as per ASTM standards, these tubes ensure impeccable strength and lasting service. Features :

Carbon Steel Tubes Standard : ASTM / SA 179 / A 210 GR.A / BS 3059 GR.360 & 440 Alloy Steel Tubes Standard : ASTM / ASME A/SA 213 Grade : T9, T11, T12, T22, T91 |

|

| Nickel & Copper Alloy Pipes | |||||||||||||||||||||||||||||||

Features :

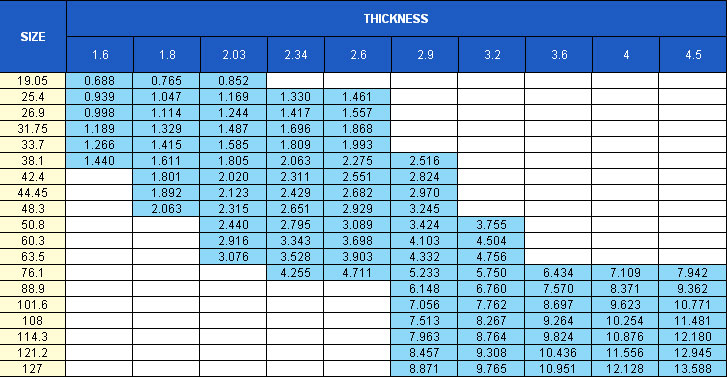

Specifications of Copper Alloy :

|

|

| Nickel & Copper Alloy Tubes | |

Specifications : Nickel Alloy Tubes Standard : ASTM / ASME SB 163 / 165 / 167 / 464/ 517 / 619 / 622 / 626 / 704 / 705 Grade : UNS 2200 (Nickel 200), UNS 2201 (Nickel 201), UNS 4400 (Monel 400), UNS 8020 (Alloy 20 / 20 CB 3), UNS 8825 Inconel (825), UNS 6600 (Inconel 600), UNS 6601 (Inconel 601), UNS 6625 (Inconel 625), UNS 10276 (Hastelloy C 276) Copper Alloy Tubes Copper Tube : Electrolytic / Dioxide Copper Nickel : ASTM / ASME SB 111 UNS NO. C 70600 ( CU -NI- 90/10) / C 71500 ( CU -NI- 70/30) / C 71640 ( CU-NI-66/30/2/2) Admiralty Brass : ASTM / ASME SB 111 UNS NO. C 44300 ( Alloy 443) Aluminum Brass : ASTM / ASME SB 111 UNS NO. C 68700 (Alloy 687) |

|

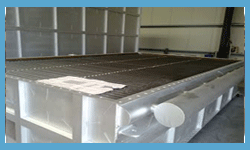

| Air Pre Heaters(APH) | |

|

|

Top